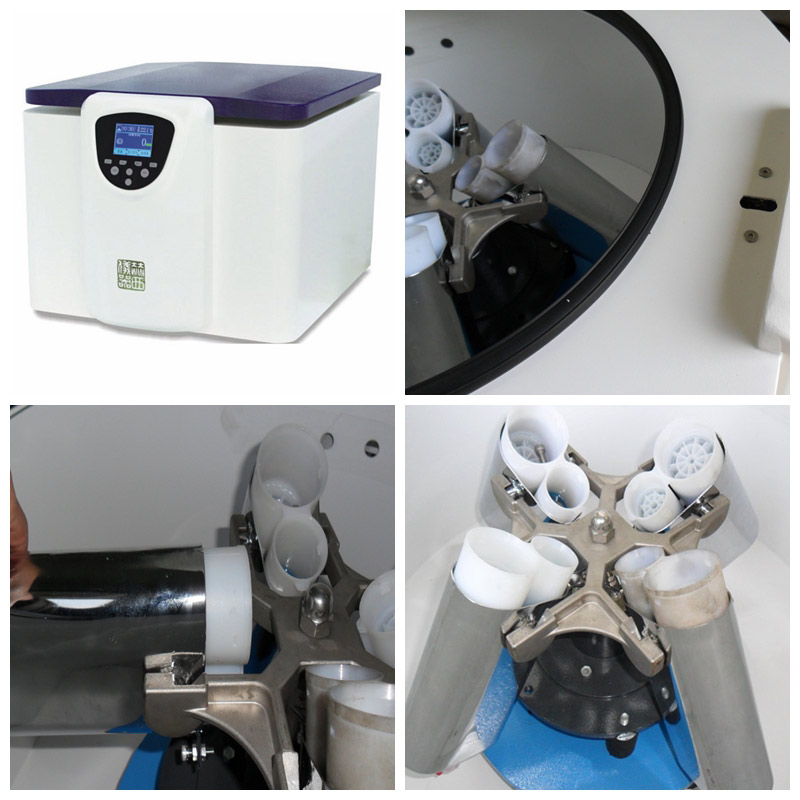

defoaming centrifuge

Specifically, the defoaming centrifuge mainly separates and purifies substances with different particle sizes and densities, so that the substances can be settled to different degrees under the action of large centrifugal force, thereby separating the required material components. In the process of material separation, an important factor can not be ignored, that is, density, especially in the application of bio-glue, density is a key element.

If there is a substance with a small difference in density in the glue, and there are many bubbles, it will affect the quality of the glue. The defoaming centrifuge can make the material perform the same speed settlement operation under the influence of the centrifugal force, so that the material is more fused and the bubbles are extracted.Defoaming centrifuge application:

In the production of high-tech products for optoelectronic devices, adhesives are required in many occasions, and the defoaming method for adhesives often affects the quality of the final product. There are some sheet materials that need to be defoamed, for example, sheets coated with ceramic slurry coated with zirconia as a substrate, which has a wide range of properties in the industry due to its good thermal stability, chemical stability and thermal shock resistance. application. The slurry of the produced sheet will have a large amount of bubbles generated during the preparation process, and the greater the viscosity, the bubbles will cause the surface quality of the sheet to deteriorate, crust, cracking, etc., so defoaming is required.

Defoaming centrifuge

Hercy defoaming centrifuge

There are three ways to remove bubbles from glue:

Centrifugation, heating, vacuuming, and centrifugation are relatively ideal. The method of heating may have some limitations, as heating may change the properties of the glue. The vacuuming method may take away the volatile components in the hardener and make the final mixing ratio incorrect. Vacuuming may also cause a film on the surface of the glue to cause the internal bubbles to fail to run out. In this context, centrifugal defoamers were invented.

The working principle of the defoaming centrifuge:

Various industrial colloids always produce certain bubbles during the preparation process. In order not to affect the use of the colloid, it is necessary to remove the bubbles, and the usual practice is to carry out defoaming by a centrifuge. Centrifugal deaerator is a centrifugal method that separates the bubbles in the material by centrifugal force. When the material is rotated at a high speed in the centrifugal defoaming machine, a centrifugal force is generated, which separates the material and the bubbles therein, and finally achieves the function of defoaming.

When the suspension containing fine particles is left to stand, the suspended particles are allowed to sink due to the action of the gravitational field. The heavier the particles, the faster the sinking, whereas the particles with a lower density than the liquid will float. The rate at which particles move under the gravitational field is related to the size, morphology, and density of the particles, and is related to the strength of the gravitational field and the viscosity of the liquid. Particles of the size of red blood cells, a few micrometers in diameter, can be observed under normal gravity. The settlement is relative, and if it is conditional, it must be subjected to external forces to move.

Defoaming centrifuge DD5 custom-made hanging cup

Defoaming centrifuge DD5 custom-made hanging cup

The settlement is proportional to the weight of the object, and the larger the particle, the faster the sedimentation. The smaller the particles, the slower the sedimentation, and the more severe the diffusion phenomenon. Therefore, it is necessary to use a centrifugal machine to generate a strong centrifugal force in order to force these particles to overcome the diffusion to produce a settling motion.

The defoaming centrifuge can be made horizontal, large and medium, and can be customized for defoaming of different sizes and lengths. The defoaming centrifuge is suitable for the dispensing tube of various manufacturers to perform defoaming treatment of various injection barrels. The defoaming function does not change the chemical properties of the product without touching the product with foreign substances.

Applicable materials:

Various glues, silver pastes, inks, greases, pastes, pharmaceuticals, cosmetic substrates, etc.

Syringe capacity: 10/30ML/50ML/70ML/100ML;

Number of syringes: customer specified, centrifugal rotor (customizable);

The last one:Low speed big capacity centrifuge